Well logging

Well integrity logging

Objectives:

- Locating of casing and downhole equipment leaks;

- Determination of leak type: casing rupture, casing collar leak;

- Detection of behind casing fluid flows;

- Measuring casing wall thickness, physical wear;

- Evaluation of cement bond between casing and cement and rock and cement;

- Assessment of top of cement;

- Evaluation of cement density, evaluation of cement sheath behind the casing

- Locating collars, centralizers and other components of well design

Well integrity logging techniques and equipment:

- Casing integrity logging, detection of behind casing fluid flows (combination toolstring AKM-38, KSA-Т12, AGAT, SOVA, GEO, SAF spectral noise logging modules, GEO-MSHA);

- Sonic cement bond logging (MAK-42, KarSar AKC78, AK-73, MAK-2, MAK-7, MAK-9);

- Scanning sonic cement bond logging (MAK-9SK, MAK-4SK);

- Gamma ray/cement bond logging (SGDT-NVc, CM-8-12c, CM-3-4);

- Electromagnetic casing inspection (EMDST-MP, MID-K);

- Casing profile logging (multifinger imaging tool GF-24).

Well log examples:

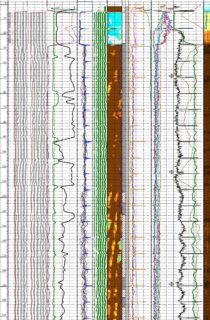

Cement bond quality evaluation using sonic scanner MAK-9SK

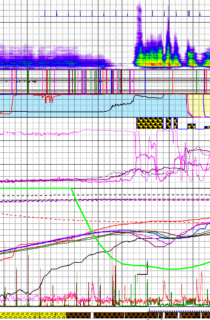

Horizontal well logging together with spectral noise logging